Silk Screen Mesh Size Chart

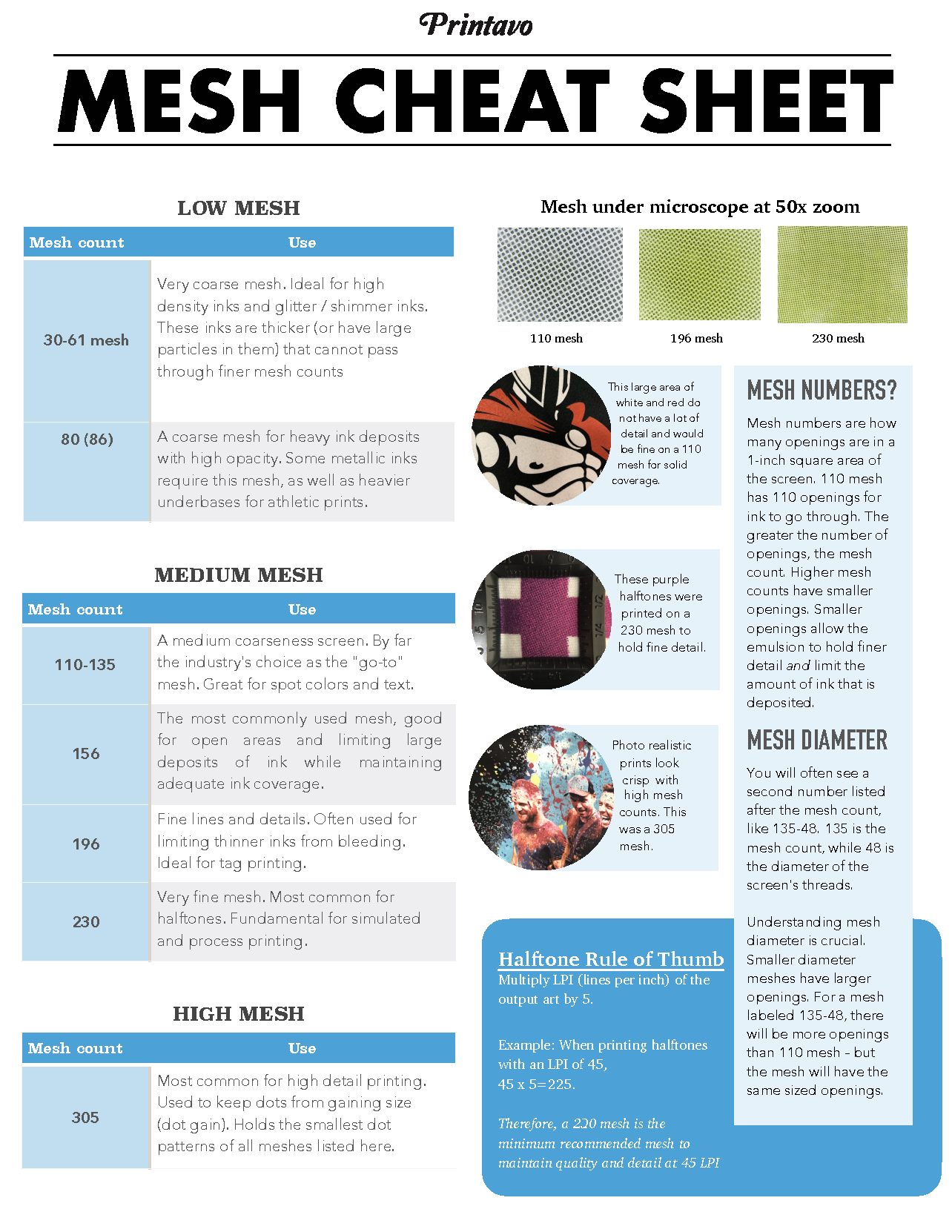

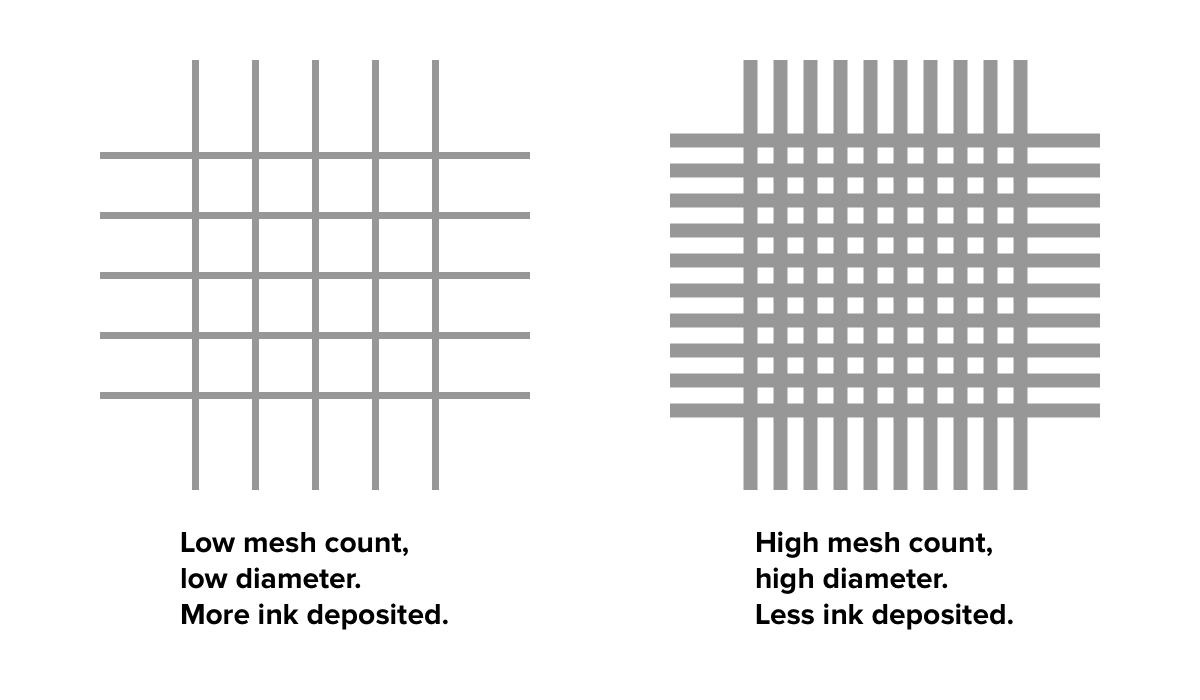

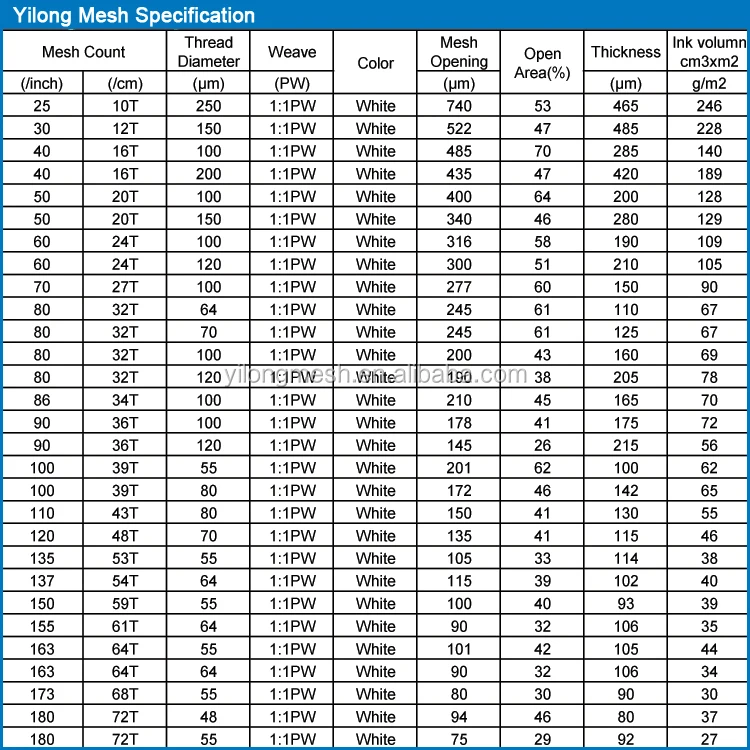

Silk Screen Mesh Size Chart - 110 mesh lays a fairly thick layer of ink down. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. How do you determine the correct size for your art, as well as selecting the appropriate silkscreen frame size to support your artwork. The most standard mesh counts in screen printing are 110 and 156. A lower mesh count, such as 40 or 60, allows more ink to pass. Below is a chart that will help you. This measurement directly impacts the amount of ink that can pass through the screen, as well as. Looking for a screen printing mesh size chart? Tune in for free print advice at norcal screen print supply. The most common screen printing mesh count for the average screen printer is a 110 for darker fabrics and a 160 for all other printing. The most standard mesh counts in screen printing are 110 and 156. Tune in for free print advice at norcal screen print supply. The most common screen printing mesh count for the average screen printer is a 110 for darker fabrics and a 160 for all other printing. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. Below is a chart that will help you. The most standard mesh counts in screen printing are 110 and 156. 110 mesh lays a fairly thick layer of ink down. Explore our comprehensive guide to choosing the right mesh count for every project. Learn how to select the ideal mesh count for various inks. The mesh size in silk screening refers to the number of threads per inch in the screen fabric. 110 mesh lays a fairly thick layer of ink down. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. 110 mesh lays a fairly thick layer of ink down. Typically, mesh sizes are measured in threads per inch (tpi),. 110 mesh lays a fairly thick layer of ink down. A lower mesh count, such as 40 or 60, allows more ink to pass. Tune in for free print advice at norcal screen print supply. Explore our comprehensive guide to choosing the right mesh count for every project. How do you determine the correct size for your art, as well. Looking for a screen printing mesh size chart? 110 mesh lays a fairly thick layer of ink down. Supplies | equipment | classes. Typically, mesh sizes are measured in threads per inch (tpi), and they vary greatly, from around 40 mesh to over 300 mesh. The most common screen printing mesh count for the average screen printer is a 110. The most standard mesh counts in screen printing are 110 and 156. 110 mesh lays a fairly thick layer of ink down. 110 mesh lays a fairly thick layer of ink down. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. Supplies | equipment | classes. 110 mesh lays a fairly thick layer of ink down. Typically, mesh sizes are measured in threads per inch (tpi), and they vary greatly, from. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. The most standard mesh counts in screen printing are 110 and 156. Before buying your screens check the tech sheets to. Explore our comprehensive guide to choosing the right mesh. Below is a chart that will help you. Supplies | equipment | classes. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. Before buying your screens check the tech sheets to. Explore our comprehensive guide to choosing the right. Typically, mesh sizes are measured in threads per inch (tpi), and they vary greatly, from around 40 mesh to over 300 mesh. Looking for a screen printing mesh size chart? Before buying your screens check the tech sheets to. 110 mesh lays a fairly thick layer of ink down. 110 mesh lays a fairly thick layer of ink down. Learn how to select the ideal mesh count for various inks. The most standard mesh counts in screen printing are 110 and 156. Explore our comprehensive guide to choosing the right mesh count for every project. Tune in for free print advice at norcal screen print supply. The mesh size in silk screening refers to the number of threads per. This measurement directly impacts the amount of ink that can pass through the screen, as well as. 110 mesh lays a fairly thick layer of ink down. The most standard mesh counts in screen printing are 110 and 156. The mesh size in silk screening refers to the number of threads per inch in the screen fabric. Explore our comprehensive. The most standard mesh counts in screen printing are 110 and 156. 110 mesh lays a fairly thick layer of ink down. How do you determine the correct size for your art, as well as selecting the appropriate silkscreen frame size to support your artwork. Start with a general introduction to screen printing mesh counts, explaining the importance of each count and why customers may seek specific meshes, from 100 mesh silk screen to 305. Typically, mesh sizes are measured in threads per inch (tpi), and they vary greatly, from around 40 mesh to over 300 mesh. 110 mesh lays a fairly thick layer of ink down. Below is a chart that will help you. The mesh size in silk screening refers to the number of threads per inch in the screen fabric. Supplies | equipment | classes. Tune in for free print advice at norcal screen print supply. Learn how to select the ideal mesh count for various inks. The most standard mesh counts in screen printing are 110 and 156. Looking for a screen printing mesh size chart? Explore our comprehensive guide to choosing the right mesh count for every project.Screen Mesh Sizes Chart What Is Standard Window Screen Mesh

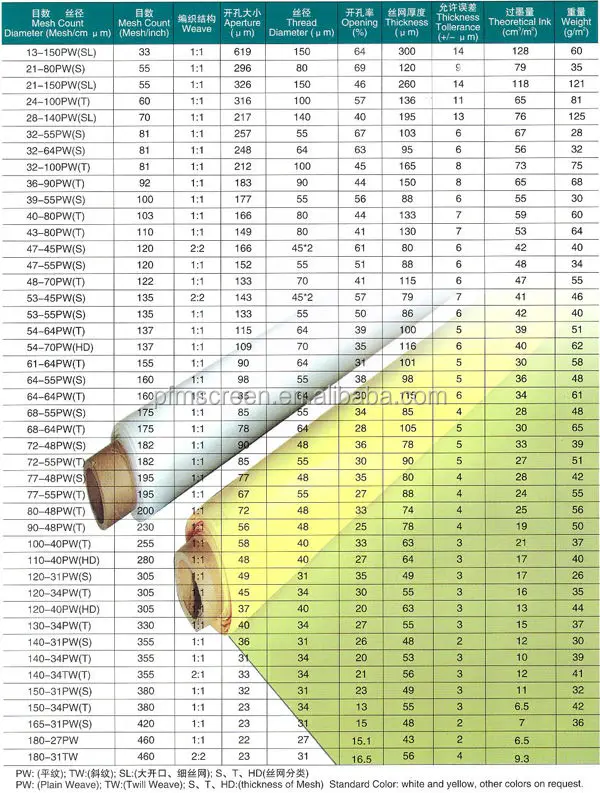

Screen Printing Size Chart Portal.posgradount.edu.pe

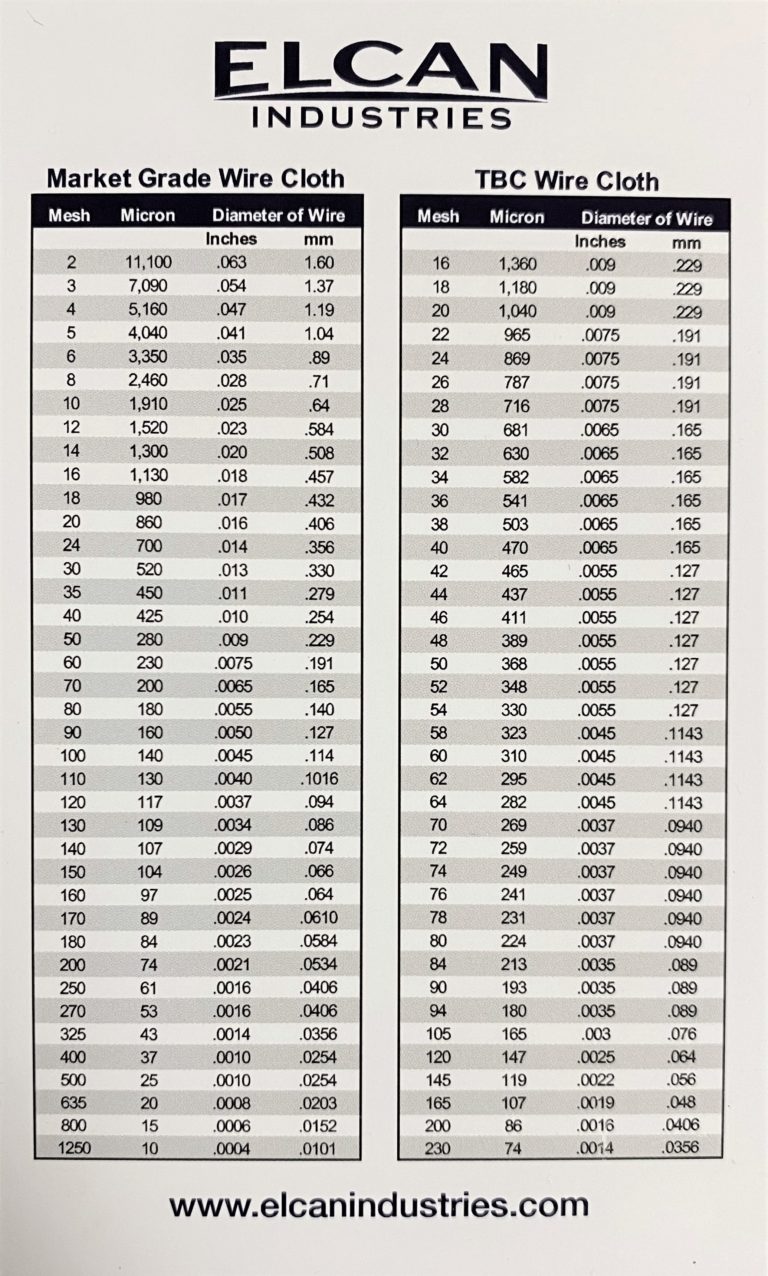

Mesh to Micron Chart Micron Size Elcan Industries

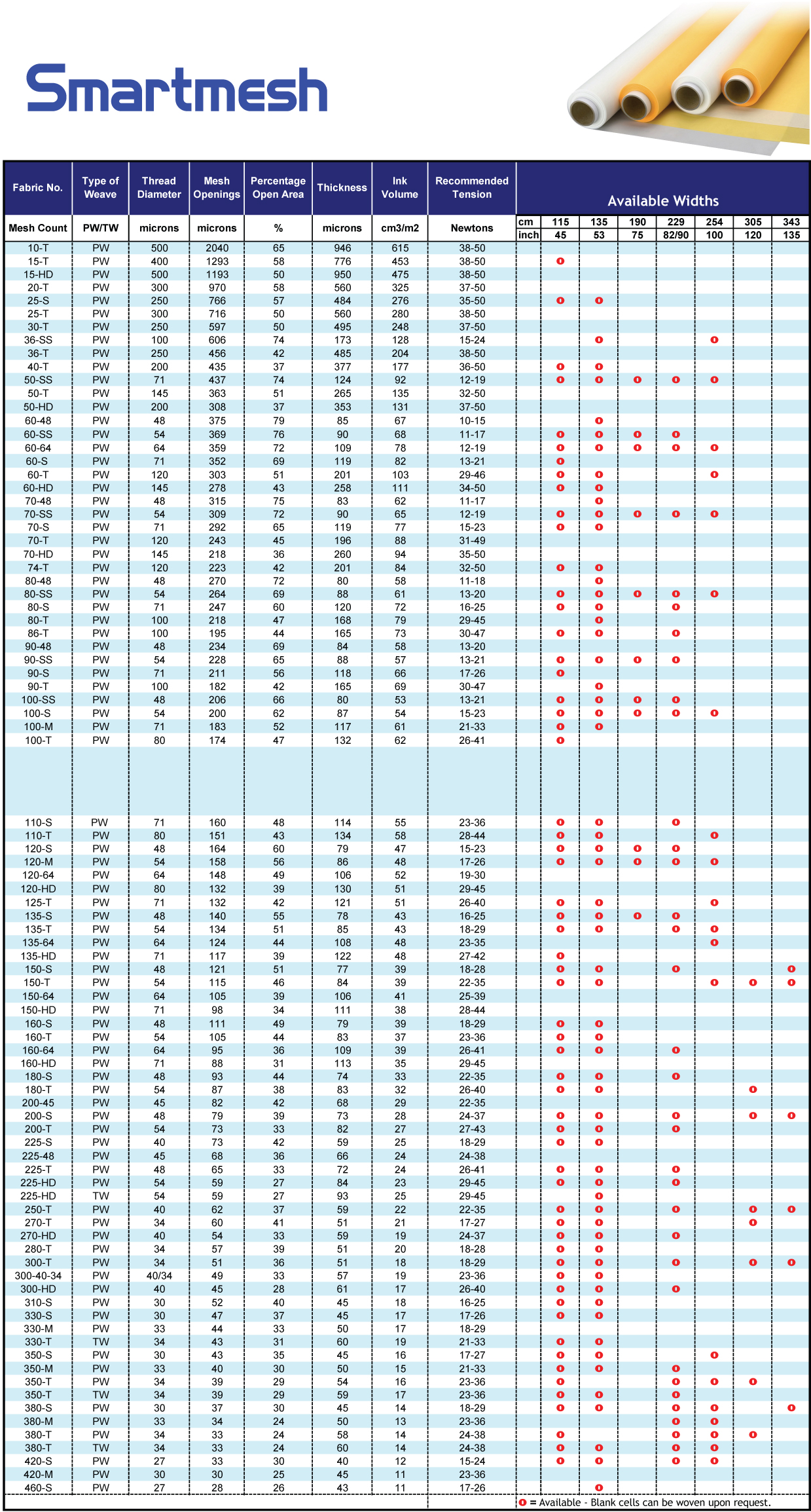

Smartmesh Chart and Tension Guide Murakami

SWECO Screen Mesh Conversion Chart PDF

Unique Screen Mesh Size Chart with Additional Standard Sizes Design Details Wire Cloth Design

Silk Screen Sizes at Alexander Tisdale blog

What Mesh Count Should I Use For Screen Printing?

What Mesh Count Should I Use For Screen Printing?

Screen Printing Mesh Chart

A Lower Mesh Count, Such As 40 Or 60, Allows More Ink To Pass.

Before Buying Your Screens Check The Tech Sheets To.

This Measurement Directly Impacts The Amount Of Ink That Can Pass Through The Screen, As Well As.

The Most Common Screen Printing Mesh Count For The Average Screen Printer Is A 110 For Darker Fabrics And A 160 For All Other Printing.

Related Post: