Kanban Flow Chart

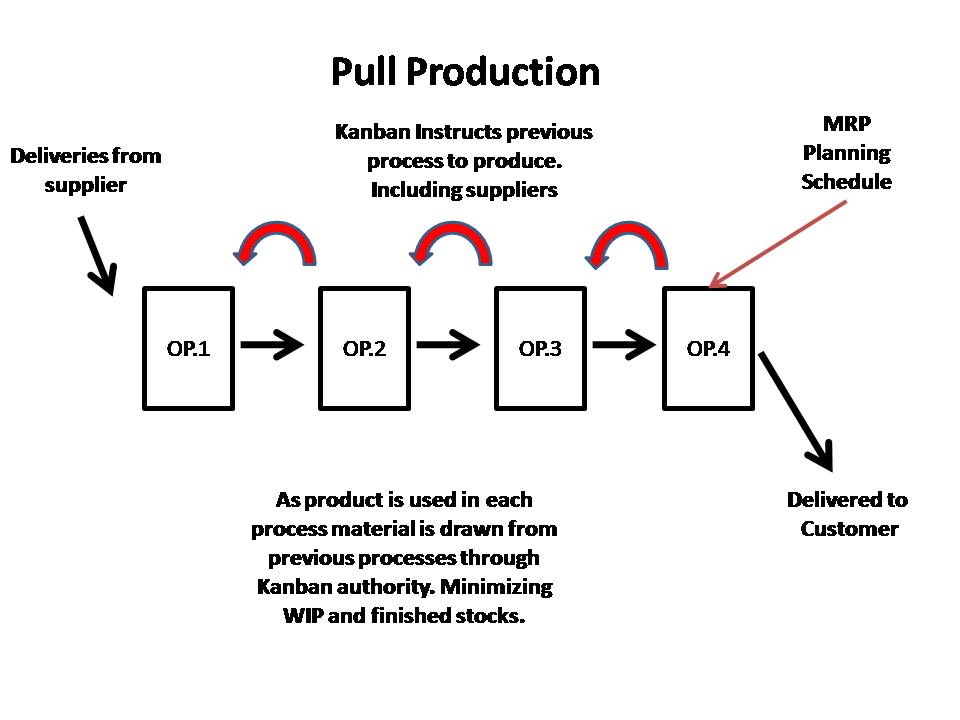

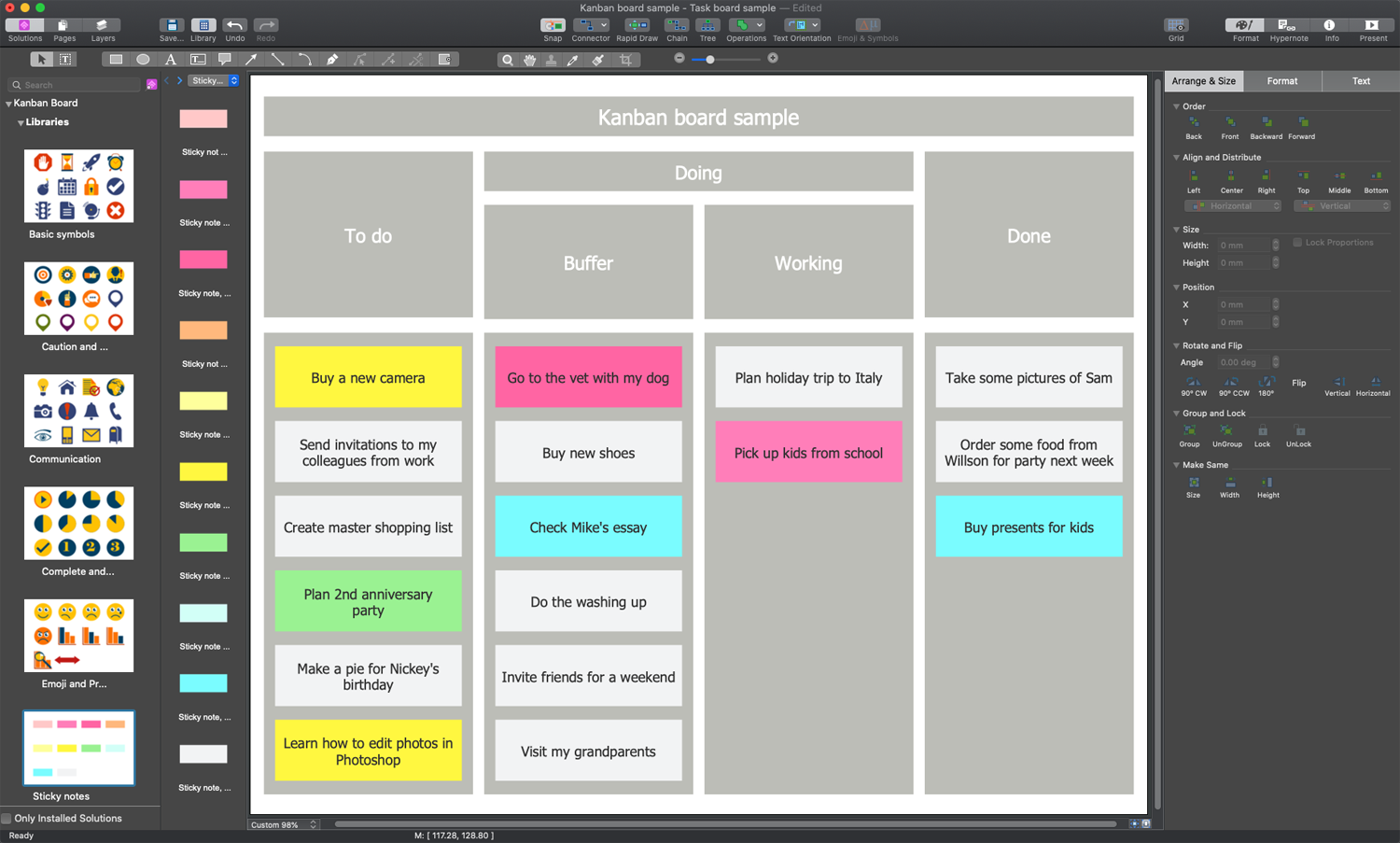

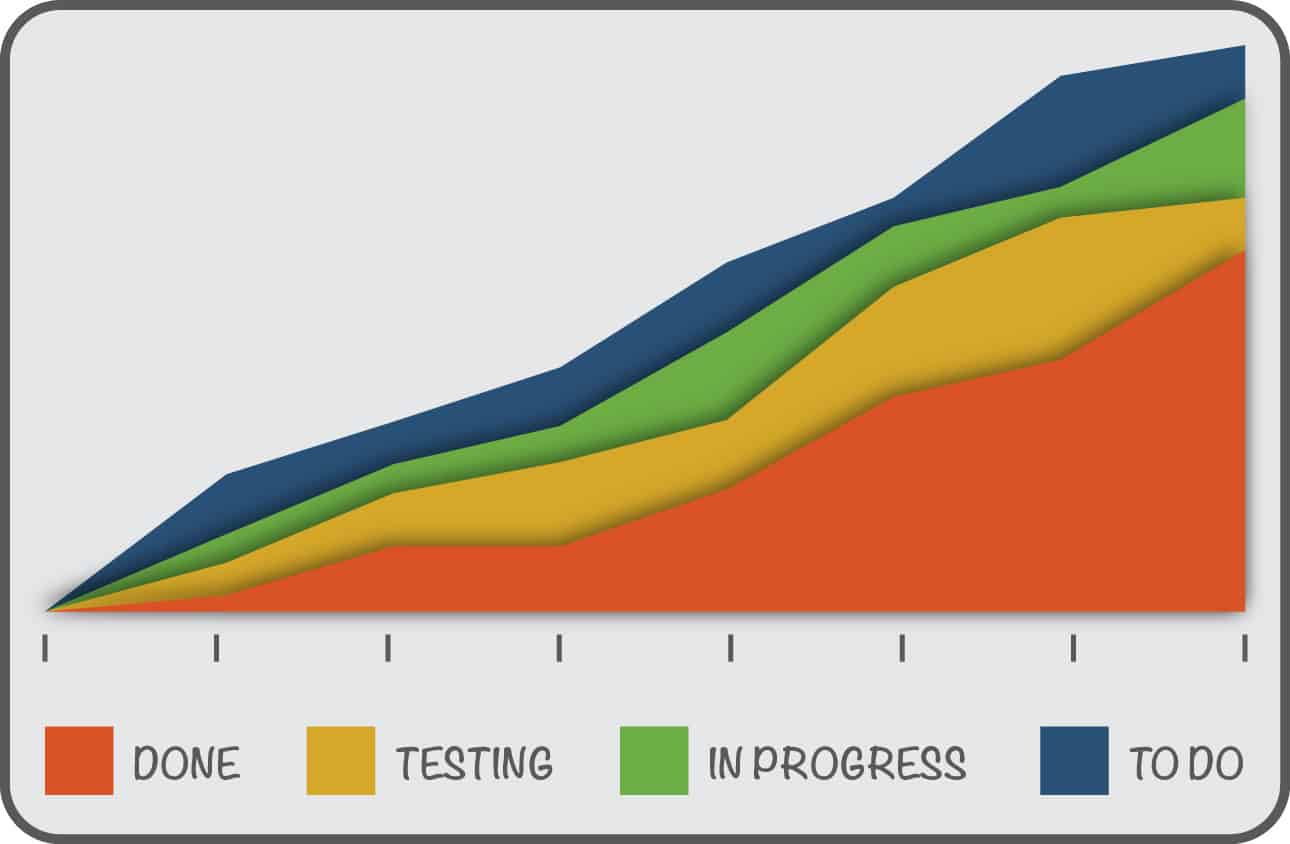

Kanban Flow Chart - It helps you visualize work, maximize. Kanban is also known as the toyota nameplate system in the automotive industry. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving services that deliver knowledge work. Kanban is a visual work management system that provides a clear representation of work progression within a process. The kanban method is an approach to evolutionary and incremental systems and process change for organizations. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. Kanban is a systematic method of work, derived from lean and agile. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. With the kanban method, you. It offers a visual depiction of both the workflow process. With the kanban method, you. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving services that deliver knowledge work. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is a systematic method of work, derived from lean and agile. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. It offers a visual depiction of both the workflow process. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. Kanban is also known as the toyota nameplate system in the automotive industry. It helps you visualize work, maximize. The kanban method is an approach to evolutionary and incremental systems and process change for organizations. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. With the kanban method, you. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is an agile management method built on a philosophy of continuous. With the kanban method, you. Kanban is also known as the toyota nameplate system in the automotive industry. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving services that deliver knowledge work. It offers a visual depiction of both the workflow process. Using the kanban method means applying a holistic way of thinking. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. It offers a visual depiction of both the workflow process. Kanban is a visual work management system that provides a clear representation of work progression within a process. Using the kanban method means applying a holistic way of thinking about your. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. It offers a visual depiction of both the workflow process. Kanban is also known as the toyota nameplate system in the automotive industry. Kanban is an agile management method built on a philosophy of continuous improvement,. With the kanban method, you. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. It helps you. It offers a visual depiction of both the workflow process. It helps you visualize work, maximize. Kanban is a visual work management system that provides a clear representation of work progression within a process. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow. It offers a visual depiction of both the workflow process. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. It helps you visualize work, maximize. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving. Kanban is also known as the toyota nameplate system in the automotive industry. With the kanban method, you. Kanban is a systematic method of work, derived from lean and agile. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is an agile management method built on a philosophy of. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is a systematic method of work, derived from lean and agile. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. The kanban method is an. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. Kanban is also known as the toyota nameplate system in the automotive industry.. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving services that deliver knowledge work. It helps you visualize work, maximize. Using the kanban method means applying a holistic way of thinking about your services with a focus on improving them from your customers’ perspective. The kanban method is an approach to evolutionary and incremental systems and process change for organizations. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Kanban is a visual work management system that provides a clear representation of work progression within a process. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. It offers a visual depiction of both the workflow process.How to structure your Kanban flow efficiently Blog

kanbantheflowstrategye284a225 Kanban is a strategy for optimizing the flow of value

How to structure your Kanban flow efficiently Blog

Experts Share The Best Kanban Tools For Today And Tomorrow

Kanban Agile Workflow Canvas by

Personal Kanban Process Flow Chart Job Analysis 6 Sigma Microsoft Project Time Management Free

Kanban Flow Chart How Kanban Methodology Can Improve Your Team Flowchart Example

Kanban Process Flow Chart Tabitomo Vrogue.co

The Kanban Method The Ultimate Beginner's Guide! Nave

Kanban Flow Chart How Kanban Methodology Can Improve Your Team Flowchart Example

Kanban Is Also Known As The Toyota Nameplate System In The Automotive Industry.

With The Kanban Method, You.

Kanban Is A Systematic Method Of Work, Derived From Lean And Agile.

Related Post:

.jpg)