Electrode Welding Chart

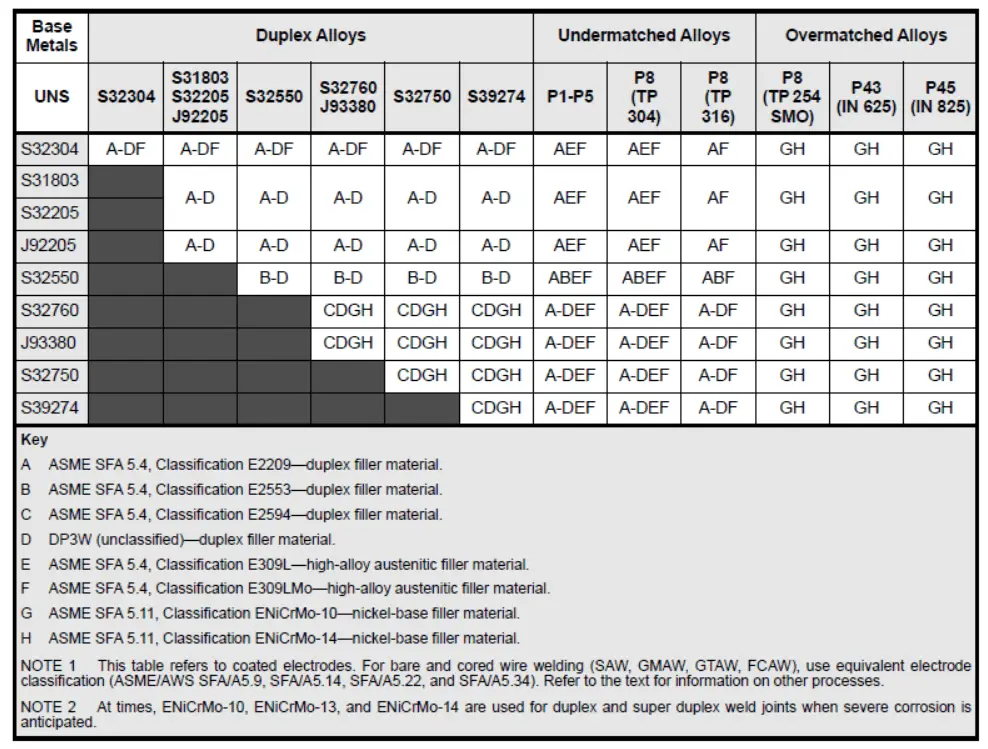

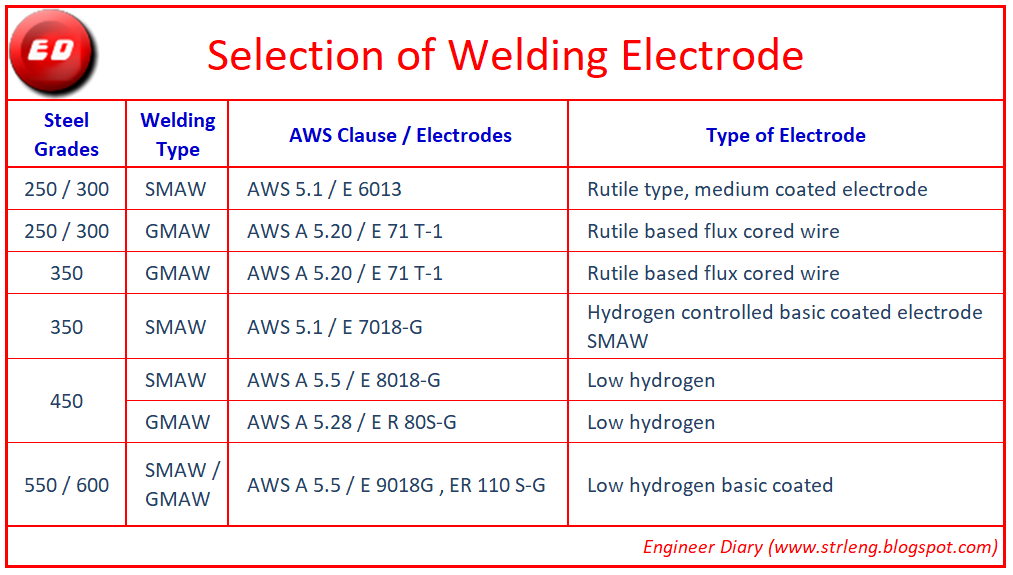

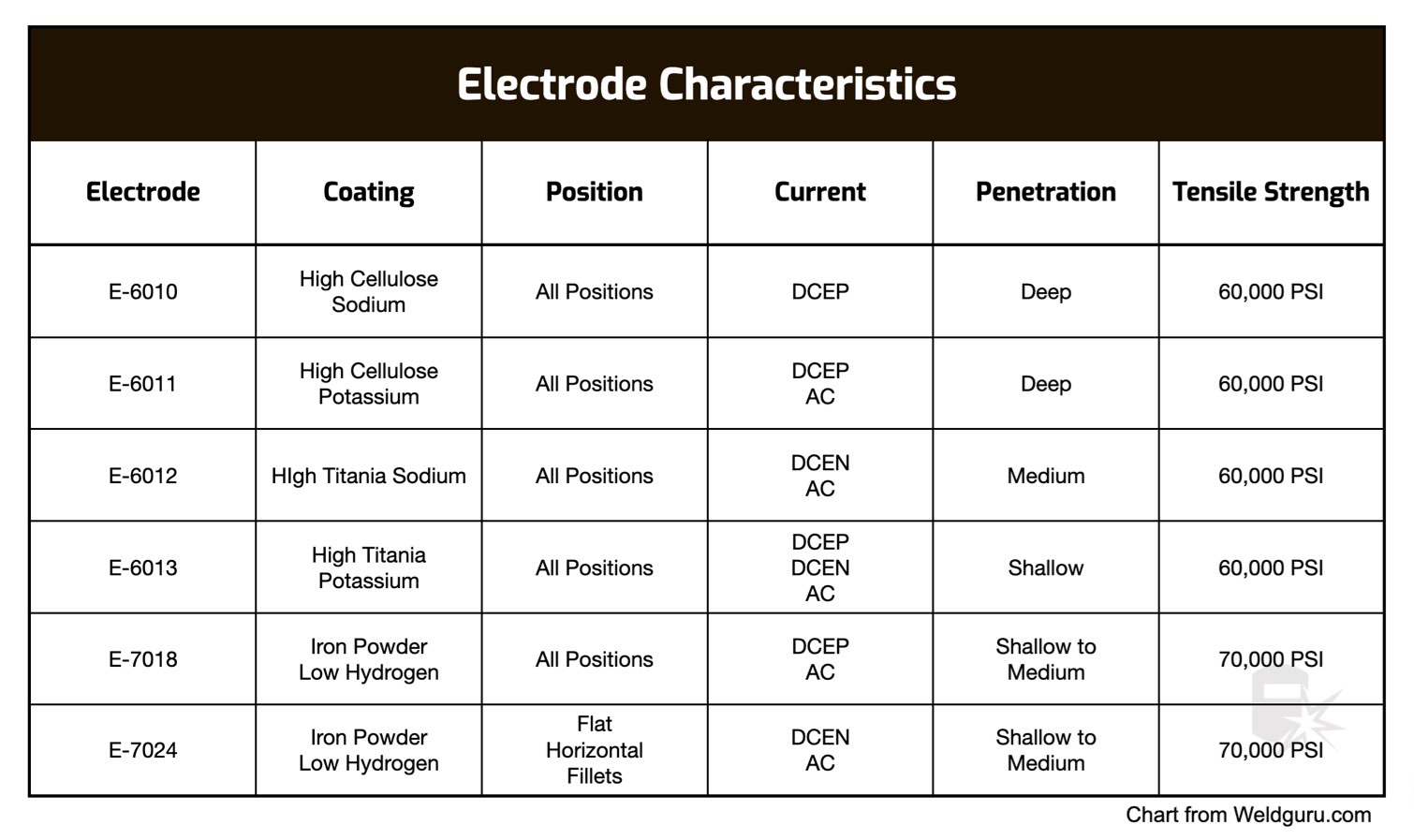

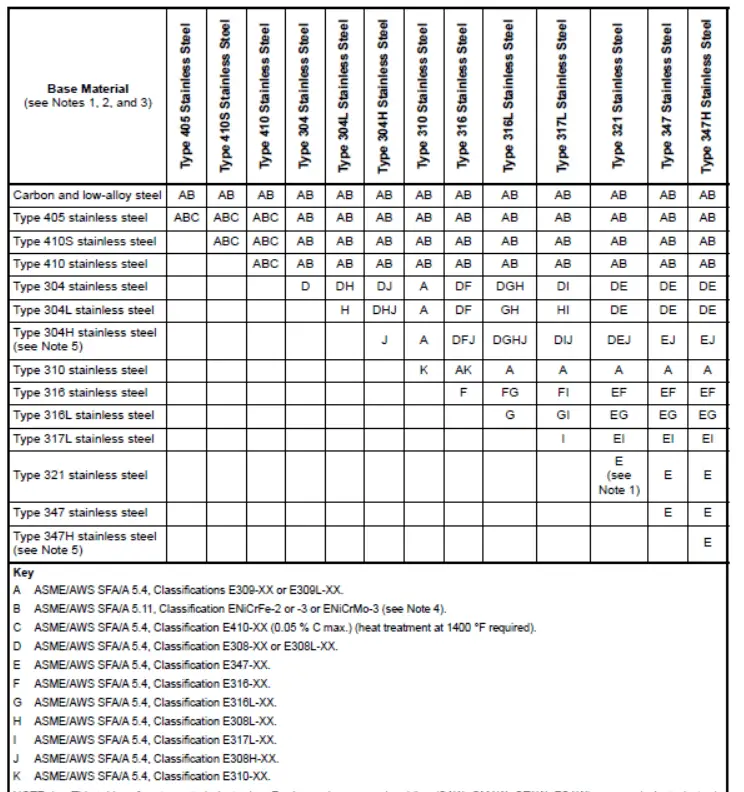

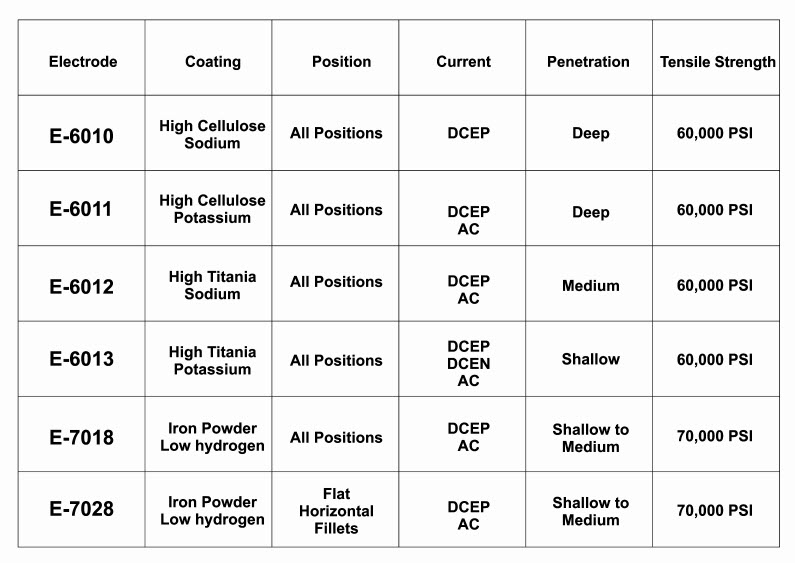

Electrode Welding Chart - Use this chart as a starting point and adjust based on your. Use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel, stainless steel, and. A stick welder settings chart gives you a quick reference for the most common electrodes and metal thicknesses. The electrode coating can help stabilize the arc, create. How to select stick welding rod type, size, and amperage. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. If you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Our powerful calculator let's you easily determine which stick electrode you need. Welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. How to select stick welding rod type, size, and amperage. Plus you'll get the most complete welding rod chart on the internet in pdf! Our powerful calculator let's you easily determine which stick electrode you need. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. An electrode chart for arc welding is a reference guide for selecting the appropriate electrode based on the welding job and materials involved. Use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel, stainless steel, and. The electrode coating can help stabilize the arc, create. Plus a chart with rod size and amperage per metal thickness in inches and mm. Use this chart as a starting point and adjust based on your. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. Our powerful calculator let's you easily determine which stick electrode you need. Welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. A stick welder settings chart gives you a quick reference for the most common electrodes and metal thicknesses. See our chart and guide on how to select the right welding rod size diameter and. Our powerful calculator let's you easily determine which stick electrode you need. How to select stick welding rod type, size, and amperage. Welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. Use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel,. If you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel, stainless steel, and. Plus you'll get the most complete. Our powerful calculator let's you easily determine which stick electrode you need. Use this chart as a starting point and adjust based on your. The electrode coating can help stabilize the arc, create. Plus a chart with rod size and amperage per metal thickness in inches and mm. Use this chart to find welding electrodes for welding duplex stainless steel,. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Use this chart as a starting point and adjust based on your. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. Plus a chart with rod size and amperage. A stick welder settings chart gives you a quick reference for the most common electrodes and metal thicknesses. Use this chart as a starting point and adjust based on your. Welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. Plus a chart with rod size and amperage per metal thickness in inches and mm. Plus. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. Our powerful calculator let's you easily determine which stick electrode you need. Electrode welding, or stick welding, uses electrode rods covered in a flux, each of which has various properties and uses. See our chart and guide on how to select the right welding. Plus a chart with rod size and amperage per metal thickness in inches and mm. Our powerful calculator let's you easily determine which stick electrode you need. How to select stick welding rod type, size, and amperage. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other. If you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Use this chart as a starting point and adjust based on your. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness. A stick welder settings chart gives you a quick reference for the most common electrodes and metal thicknesses. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Welding electrode. If you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Plus you'll get the most complete welding rod chart on the internet in pdf! See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. The electrode coating can help stabilize the arc, create. Use this chart to find welding electrodes for welding duplex stainless steel, super duplex stainless steel, and welding duplex stainless steel to carbon steel, stainless steel, and. Our powerful calculator let's you easily determine which stick electrode you need. Plus a chart with rod size and amperage per metal thickness in inches and mm. Welding electrode types, meaning, chart, table, uses, coating, size, symbols, numbers, classification, and defects. Use this chart as a starting point and adjust based on your. Electrode selection is critical to ease of cleanup, weld strength, bead quality, and minimizing any spatter. An electrode chart for arc welding is a reference guide for selecting the appropriate electrode based on the welding job and materials involved.Free PDF Chart for Welding Electrode and Filler wire Selection

Welding Electrode Selection Chart

Electrode Amperage Chart — Baker's Gas & Welding Supplies, Inc.

Welding Electrode Chart and Selection Weld Guru

Free PDF Chart for Welding Electrode and Filler wire Selection

Welding Electrode Selection Chart Pdf

Arc Welding Rods Guide

Electrode Chart For Arc Welding at Patrick Purcell blog

Free PDF Chart for Welding Electrode and Filler wire Selection

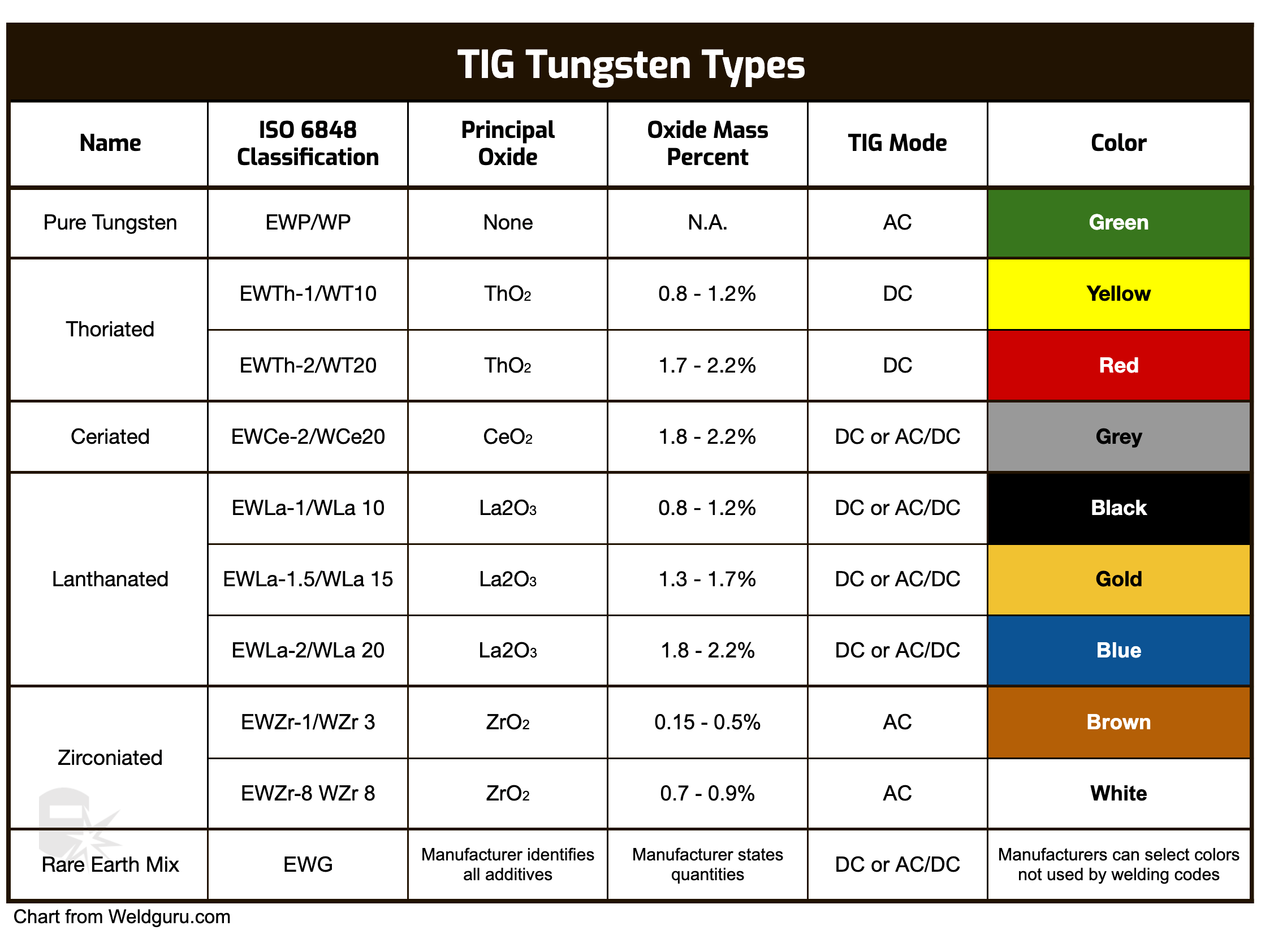

tungsten welding color chart Tig welding tungsten electrode electrodes mig weld m10

A Stick Welder Settings Chart Gives You A Quick Reference For The Most Common Electrodes And Metal Thicknesses.

Electrode Welding, Or Stick Welding, Uses Electrode Rods Covered In A Flux, Each Of Which Has Various Properties And Uses.

How To Select Stick Welding Rod Type, Size, And Amperage.

Related Post: