Bearing Press Fit Tolerance Chart

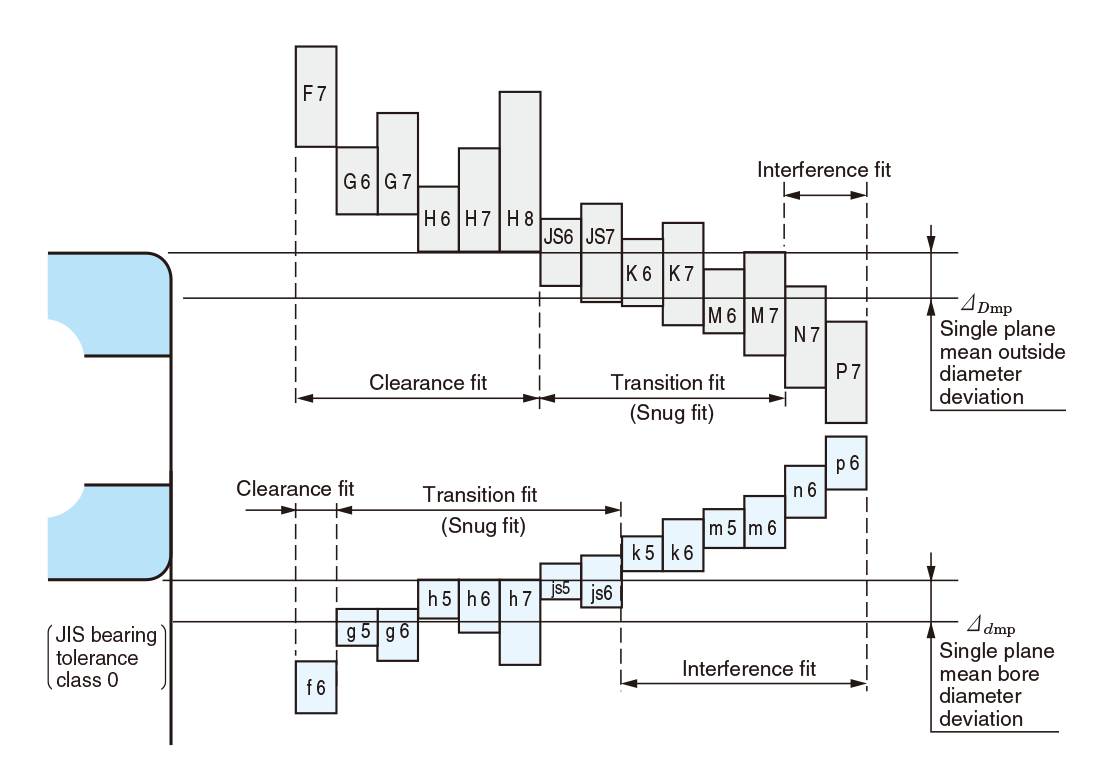

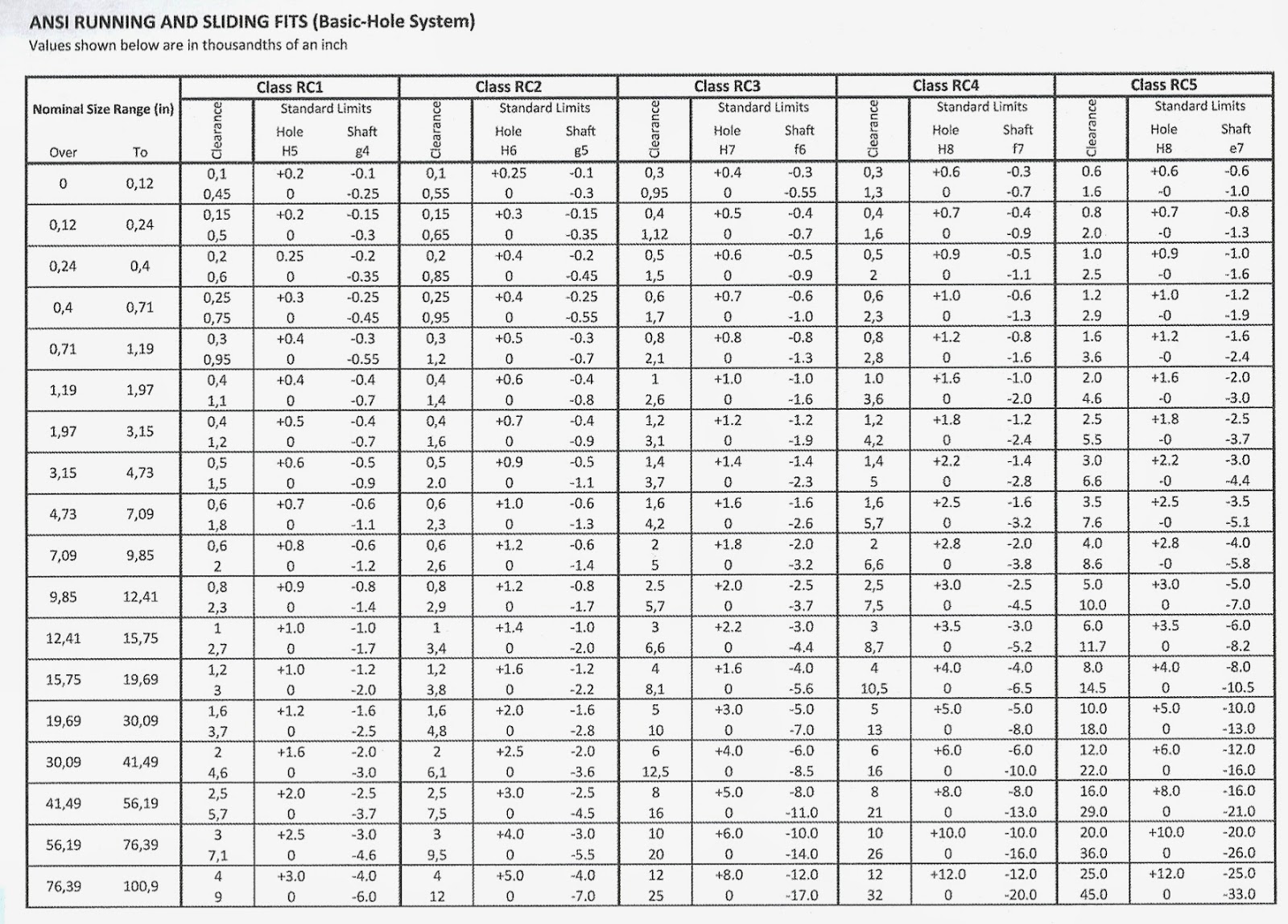

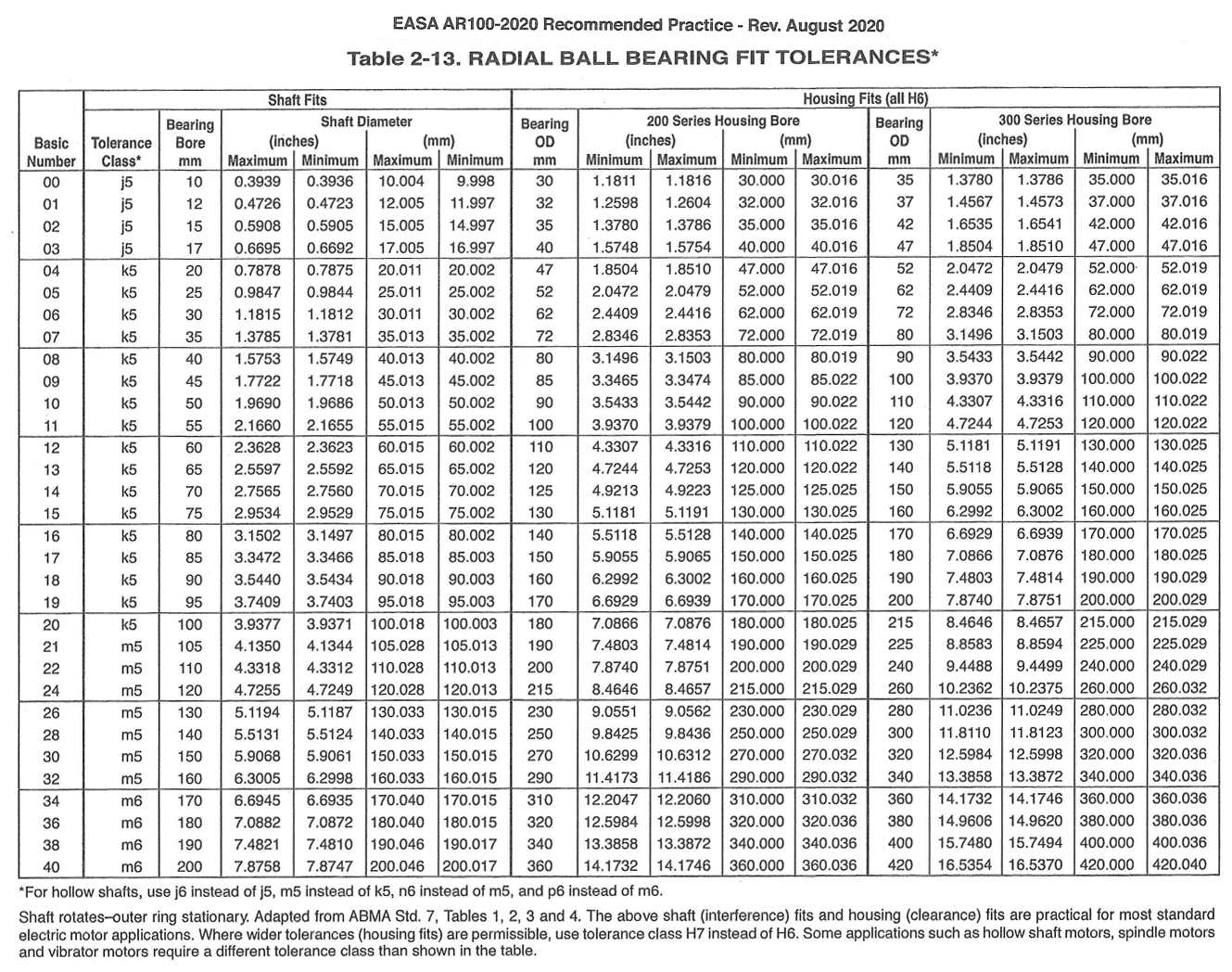

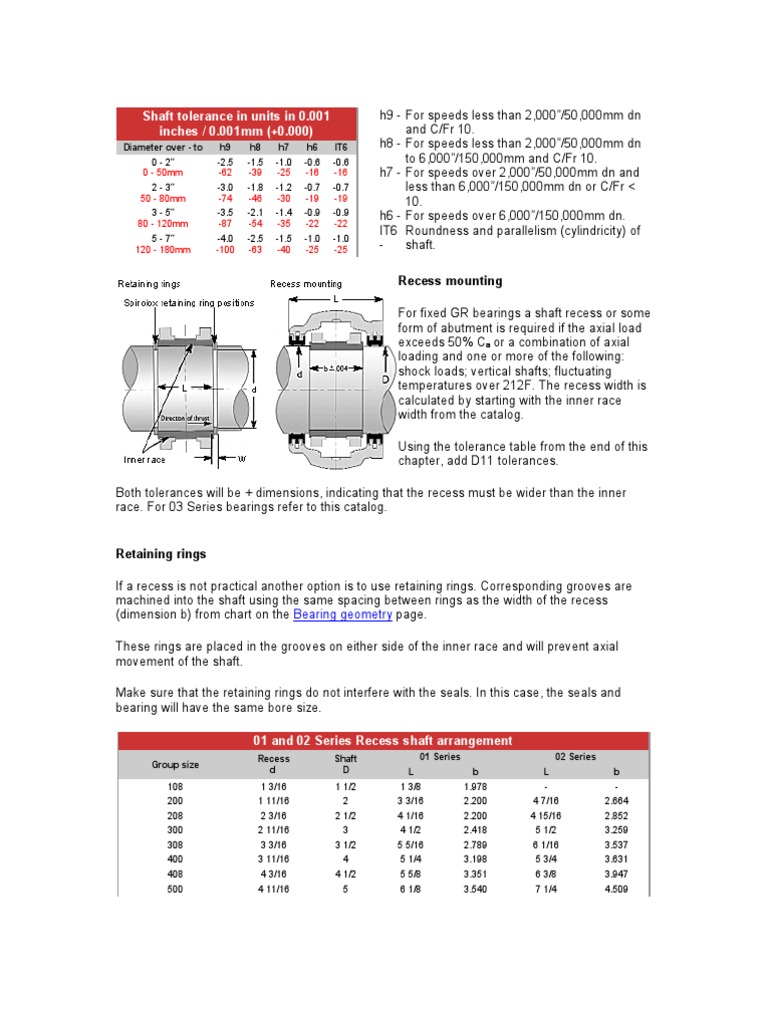

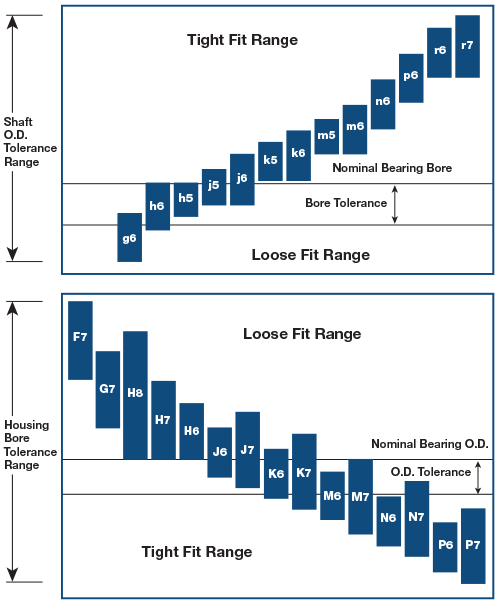

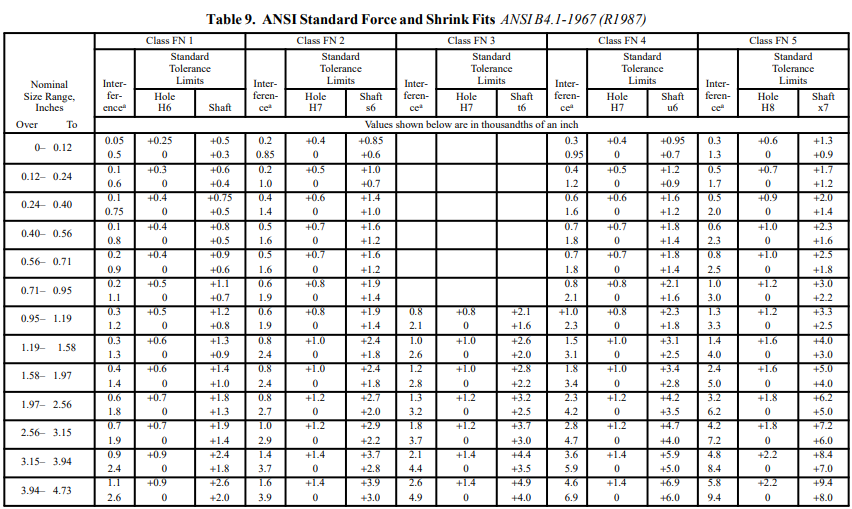

Bearing Press Fit Tolerance Chart - This calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. For a schematic representation of the most common rolling bearing fits. Bearing fit is governed by the selection tolerances for bearing shaft diameters and housing bore diameters. These should enable you to determine easily the maximum and minimum. The rpm adjustment factor is based on gmn ball bearing. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. Bearing fit is governed by the selection tolerances for bearing shaft diameters and housing bore diameters. Tight fits are also called interference or press fits, because bearings in these assemblies are pressed onto shafts. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). The following tables provide recommendations for tolerances of shaft and housing. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical. These should enable you to determine easily the maximum and minimum. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. Reference hole class of tolerance range for shafts clearance fit transition fit interference fit fixing the rim of a drive gear and a boss together attaching and fixing a bearing bushing. The rpm adjustment factor is based on gmn ball bearing. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. Tight fits are also called interference or press fits, because bearings in these assemblies are pressed onto shafts. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). Metric size standard dimension tolerances for. The rpm adjustment factor is based on gmn ball bearing. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical. The following tables provide recommendations for tolerances of. Bearing fit is governed by the selection tolerances for bearing shaft diameters and housing bore diameters. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. This calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. Complete charts for. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits. This article discusses everything you need to learn about tolerance in press fit, factors. The following tables provide recommendations for tolerances of shaft and housing. The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit. For a schematic representation of the most common rolling bearing fits. The following tables provide recommendations for tolerances of shaft and housing. Reference hole class of tolerance range for shafts clearance fit transition fit interference fit fixing the rim of a drive gear and a boss together attaching and fixing a bearing bushing. The tables in this section provide information. Tight fits are also called interference or press fits, because bearings in these assemblies are pressed onto shafts. This calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. These should enable you to determine easily the maximum and minimum. The rpm adjustment factor is based on gmn ball bearing. The. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. These should enable you to determine easily the maximum and minimum. For a schematic representation of the most common rolling bearing fits. Metric size standard dimension tolerances for bearing shaft diameters and housing bore diameters are governed by iso 286. Metric size standard dimension tolerances for bearing shaft diameters and housing bore diameters are governed by iso 286 and jis b 0401 (dimension tolerances and fits). For a schematic representation of the most common rolling bearing fits. A press fit tolerance chart is a tabular format ( sometimes graphs) illustrating nominal sizes and permissible deviation ranges for tolerances. This article discusses everything you need to learn about tolerance in press fit, factors influencing tolerances in press fits, calculations for press fit tolerances, and practical. Complete charts for p7/h6 press fit per iso 286, including size limits for hole and shaft and clearance classification data. The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits (fig. This calculator helps you find the right machined shaft and housing tolerance recommendations to ensure a press fit is achieved. Tight fits are also called interference or press fits, because bearings in these assemblies are pressed onto shafts. Reference hole class of tolerance range for shafts clearance fit transition fit interference fit fixing the rim of a drive gear and a boss together attaching and fixing a bearing bushing. The rpm adjustment factor is based on gmn ball bearing. The tolerance position is indicated by letters (upper case for housings, lower case for shafts).Tolerance and fit for shaft & housing Basic Bearing Knowledge Koyo Bearings /JTEKT CORPORATION

Press Fit Bearing Tolerance Chart Portal.posgradount.edu.pe

Press Fit Bearing Tolerance Chart Portal.posgradount.edu.pe

Tolerance Charts for Bearings — Electric Motor Bearings

Bearing Fit Chart Bearing (Mechanical) Engineering Tolerance

Dowel Press Fit Tolerance Chart vrogue.co

What Tolerance For Bearing Fit at Virginia Corner blog

How To Use Press Fit Tolerance

Bearing Press Fit Tolerance Chart

Dowel Pin Hole Tolerance Chart

The Following Tables Provide Recommendations For Tolerances Of Shaft And Housing.

Bearing Fit Is Governed By The Selection Tolerances For Bearing Shaft Diameters And Housing Bore Diameters.

These Should Enable You To Determine Easily The Maximum And Minimum.

Related Post: